In the production workshop of CPO Cool Power, a dynamic“intelligent manufacturing” saga for motorcycle cylinder heads unfolds. A batch of self – branded cylinder heads, a testament to the factory’s strength and innovative spirit, is gearing up for overseas markets, set to infuse “China – made, Smart – crafted” prowess into the global motorcycle industry.

I. Cutting – edge Equipment: The Backbone of Production

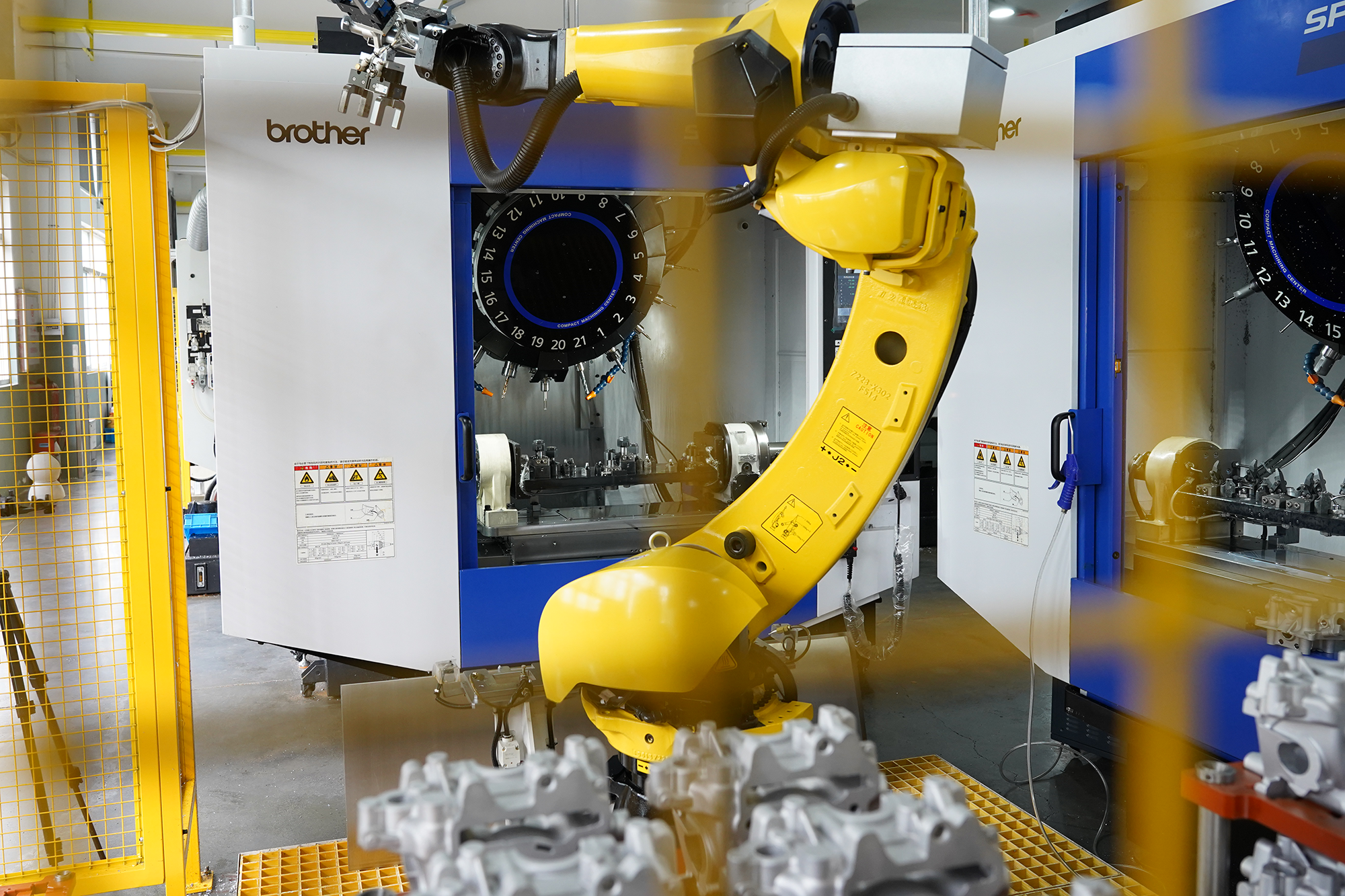

Enter the workshop, and the air buzzes with automation and intelligence. A yellow robotic arm moves with precision, like an industrial “artisan”, collaborating with high – end machining centers such as “brother” to meticulously shape motorcycle cylinder head blanks. From post – casting rough machining to the crafting of key holes and air passages with an accuracy of ±0.01mm, the production line, forged by advanced equipment, dissects and reorganizes the intricate cylinder head manufacturing process. With millimeter – even micrometer – level precision control, each cylinder head emerges as a “masterpiece of craftsmanship”, ready to deliver stable and reliable performance to overseas customers.

II. Exquisite Craftsmanship: Decoding Quality

Right from raw material selection, the factory enforces strict quality checks. High – strength aluminum alloy or cast iron undergoes precise smelting, degassing, and slag removal, laying a robust “foundation” for the cylinder head. In casting, processes like sand casting and metal – mold casting are adaptively used, paired with low – pressure casting technology, ensuring the cylinder head’s internal structure is dense and air passages unobstructed. During mechanical processing, multi – axis linkage machining centers finely mill and grind critical components such as valve seat ring holes. Surface roughness is controlled within Ra 1.6μm, guaranteeing engine performance and showcasing the factory’s pursuit of ultimate craftsmanship, thus giving self – branded cylinder heads a quality edge in overseas markets.

III. Scale Meets Quality: A Showcase of Factory Might

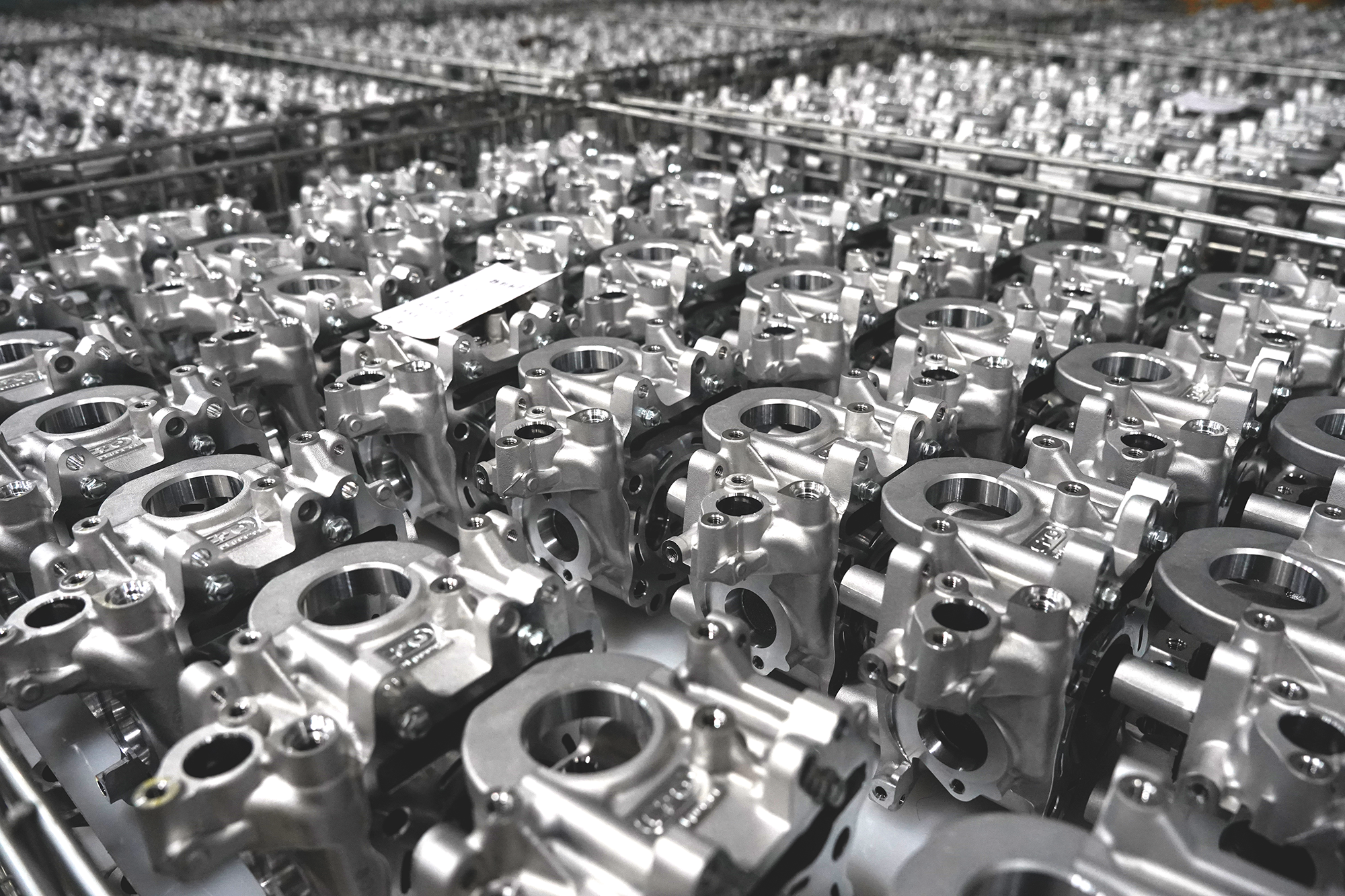

In the workshop, neatly arranged semi – finished and finished motorcycle cylinder heads stand as a testament to the factory’s large – scale production capabilities. From batch – producing cast blanks to the seamless flow of mechanical processing, surface treatment, and the orderly progression of final inspection and packaging, the mature production system harmoniously blends “quantity” and “quality”. Each cylinder head undergoes rigorous tests – leakage testing, coordinate measuring, and non – destructive flaw detection – ensuring zero defects in products destined for overseas.

IV. Self – brand Going Global: Spreading “China – made, Smart – crafted” Value

This batch of motorcycle cylinder heads, traveling overseas under a self – CPO brand, reflects the factory’s long – term investment in R & D and brand building. From designing products to suit overseas market needs, integrating advanced manufacturing concepts in production, to gradually refining packaging and after – sales systems, the factory leverages its “end – to – end” strength to establish the self – brand as a “Chinese hallmark” recognized overseas. As these cylinder heads make their global journey, the factory will keep forging ahead, empowering more “China – made, Smart – crafted” motorcycle parts to navigate overseas markets and pen an industrial legend unique to Chinese factories.