In the field of mechanical manufacturing, although small screws seem insignificant, they play a crucial role in various types of equipment. The stable operation of carburetors is even more inseparable from precise screw accessories. Today, we step into CPO’s production workshop to explore the complete birth process of carburetor screw accessories from raw materials to finished products.

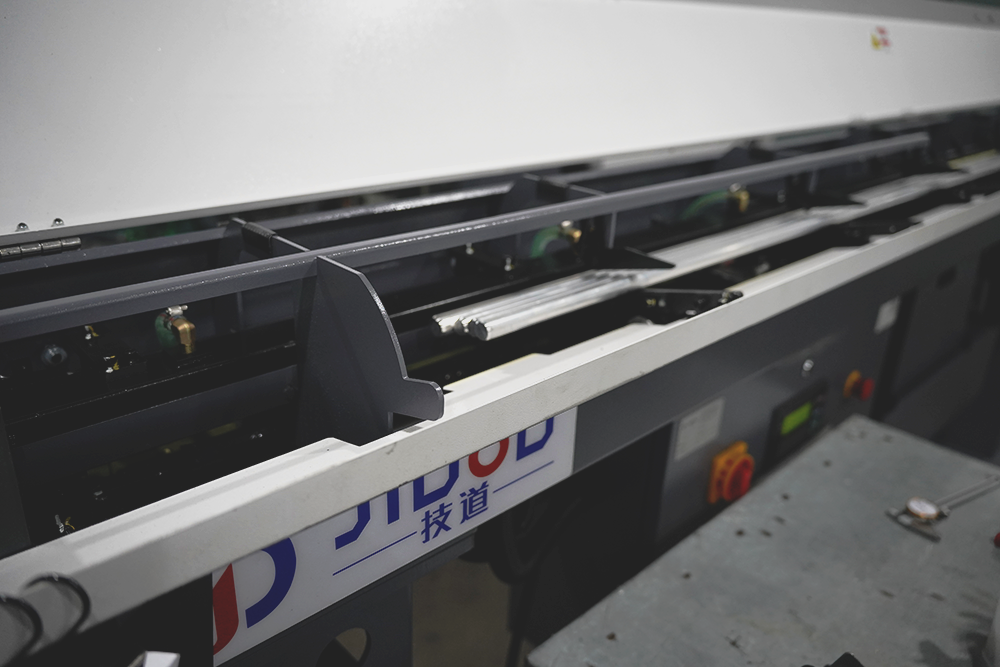

1. CPO’s Professional Processing Equipment Lays a Solid Foundation for Carburetor Accessories Production

In CPO’s production workshop, professional processing equipment is neatly arranged. Precision machinery is one of the core pieces of equipment for screw processing. Relying on its accurate mechanical structure and control system, it provides a basic guarantee for the dimensional accuracy and thread regularity of screws. At the same time, it also ensures that each screw can meet the designed tolerance range during processing. Laying a solid quality foundation for the subsequent assembly of carburetors.

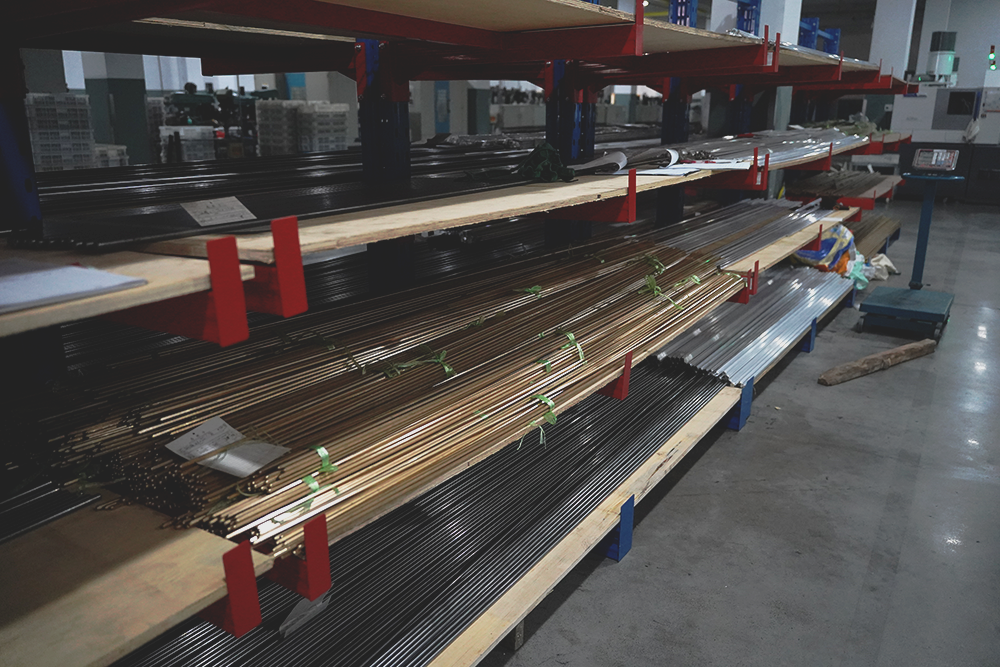

2. Strict Selection of Raw Materials for Carburetor Accessories to Control the Source Quality of Carburetors

High-quality products start from high-quality raw materials. In the raw material storage area of the workshop, various metal bars are neatly stacked on special shelves. These strictly selected metal materials meet the standards in terms of composition and physical properties. As the “base material” of carburetor screws, they determine key characteristics of screws such as strength and wear resistance. Only when the source materials meet the requirements can a foundation be laid for the subsequent production of reliable screw accessories.

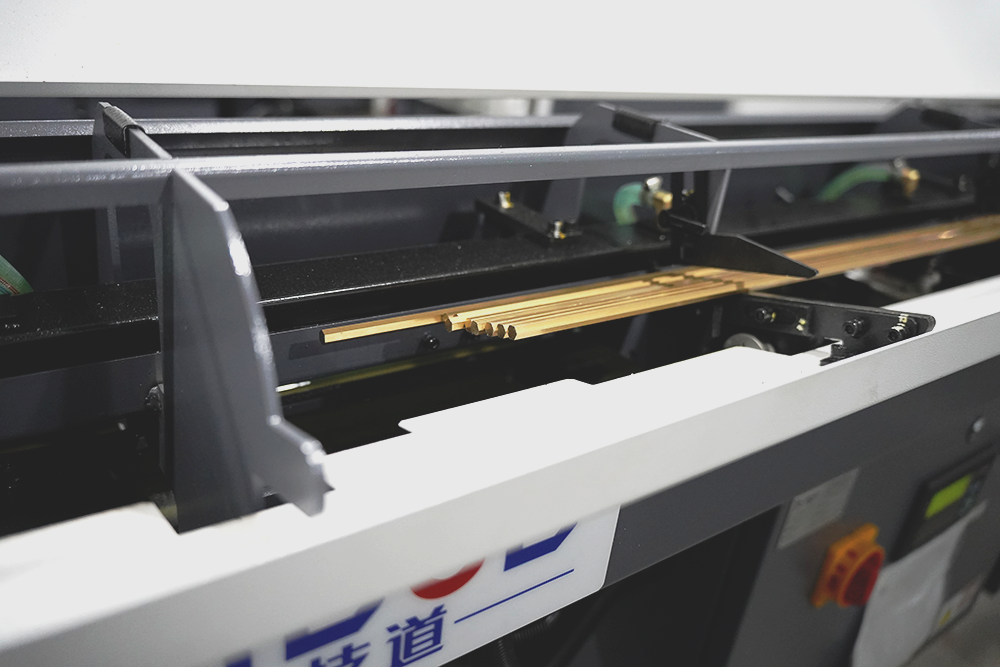

3. Precision Processing: Carving the Core Components of Carburetors

When raw materials enter the processing stage, they usher in a crucial step of “transformation”. At the processing station, metal bars are gradually carved into screws with precise threads through processes such as cutting and tapping by equipment. The newly processed screws have a smooth surface, clear threads, and regular and uniform hexagonal nuts. Each screw also needs to undergo dimensional inspection and appearance inspection. It ensures that parameters such as thread depth and nut flatness meet the assembly requirements of carburetors.

From the precise processing of professional equipment to the strict selection of raw materials, crafting each screw with precision. The production process of CPO carburetor screw accessories reflects CPO’s pursuit of refined and professional manufacturing concepts in every aspect. It is precisely these rigorous procedures that make seemingly ordinary screws a reliable guarantee for the stable operation of CPO carburetors.