In the motorcycle EFI system, the throttle body serves as the “central nervous system” for intake control, directly determining the engine’s power output, fuel economy, and operational stability. The flange structure of the throttle body, as a key transitional component of the intake channel, is a core detail affecting intake efficiency and airflow stability. Leveraging years of precision manufacturing experience, CPO Cool Power has officially mass-produced this high-specification motorcycle EFI throttle body flange assembly. With military-grade precision and innovative design, it provides excellent core component solutions for global motorcycle manufacturers and the after-sales market.

Innovative Structural Design, Reshaping the New Benchmark of Intake Efficiency

The CPO Cool Power motorcycle EFI throttle body flange assembly adopts a 45° precision chamfering process to create the flange structure, with a chamfer depth controlled at 0.25mm, forming a standard 0.25mm*90° flange shape. This optimized design completely solves the pain points of airflow eddies and unstable flow easily generated at the port of traditional throttle channels, allowing intake airflow to pass through the throttle orifice more smoothly, achieving a high degree of consistency in intake flow, and providing a stable airflow foundation for the engine ECU (Electronic Control Unit) to accurately regulate the air-fuel ratio.

The assembly adopts an integrated one-piece design concept, seamlessly connecting the flange structure with the main air channel and auxiliary air channel of the throttle body. Combined with high-precision sealing ring sealing treatment, it effectively eliminates air leakage problems that are prone to occur in traditional split structures, ensuring no lag in intake pressure transmission. This allows the sensor to sense changes in intake pressure in real time and feed them back to the control unit, significantly improving the response speed and control precision of the EFI system. At the same time, the compact structural design reduces pipeline redundancy, not only enhancing the aesthetics of the vehicle assembly but also improving the operational reliability of the components under complex working conditions.

Strict Craftsmanship and Materials, Forging Excellent Durability

In terms of material selection, CPO Cool Power adheres to quality first. The main body of the throttle body is made of high-strength copper, and the flange part undergoes special hardening treatment, featuring excellent wear resistance and corrosion resistance. It can withstand high temperatures, vibrations, and oil-gas erosion in the engine compartment for a long time, greatly extending the product service life. We equip the outer edge of the valve core with multiple sets of R-arc cam structures. We adopt a necking connection process to fit these cam structures closely with the valve body. This design enables the inner wall of the valve body to embed into the grooves between the cams, thus achieving all-round sealing. It effectively prevents side leakage and further ensures the stability of the intake system.

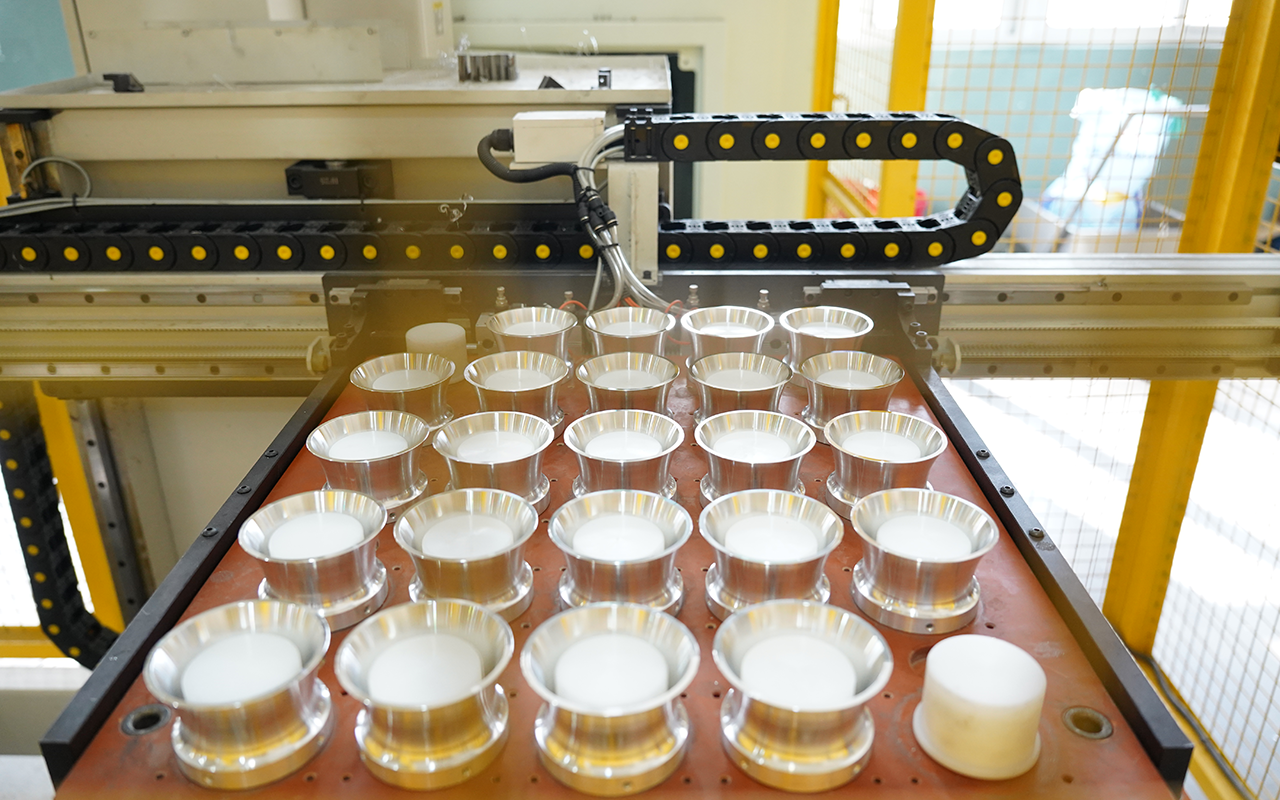

During the production process, the assembly is fully precision-machined using cutting-edge equipment at CPO Cool Power’s modern production bases. From raw material cutting, chamfering forming to integrated assembly, each process implements strict quality inspection standards, and the dimensional accuracy is controlled within the micron range. To meet the adaptation needs of different displacements and models, the product can provide customized production services. By adjusting the flange angle, throttle orifice diameter and length ratio, it meets the intake control needs of various motorcycle engines, with adaptability covering various motorcycle scenarios such as commuting and sports off-roading.

Core Performance Advantages, Empowering All-Condition Driving Experience

The mass production of this EFI throttle body flange assembly brings multi-dimensional performance improvements to motorcycles: in terms of power output, the stable intake flow makes fuel and air mixing more sufficient, the air-fuel ratio control more precise, the engine power response more rapid, the acceleration process smooth without jerking, and the power reserve more sufficient during medium and high-speed driving; in terms of fuel economy, precise intake control effectively avoids fuel waste, and compared with traditional throttle components, it can achieve a certain reduction in fuel consumption, saving users’ usage costs.

Under idle and low-temperature conditions, the assembly cooperates with the idle air control valve of the auxiliary air channel to accurately adjust the intake volume, ensuring fast and smooth engine cold start, stable low-temperature idle operation, and significantly shortened warm-up process, effectively solving common problems such as difficult start-up in winter and unstable idle speed. At the same time, the optimized airflow design reduces intake noise, and combined with the vibration suppression structure of the component, it significantly improves the quietness of the vehicle during driving, bringing users a more comfortable driving experience.

CONTACT US!

Address

No. 8 Zhongxing Road, Guanling Town, Fuding City, Fujian Provi, China

Email Us

China : [email protected]

Indonesia agent : [email protected]

Thailand agent : [email protected]

Call Us

China General Manager : +86 180-5972-7660

China Sales Manager : +86 187-5038-9478

Indonesia General Manager : +62 811-124-2882

Thailand General Manager : +66 080-277-5290

* Sincerely recruit agents from all countries

Contact information:

General Manager Tel:+86 180-5972-7660

Email:[email protected]