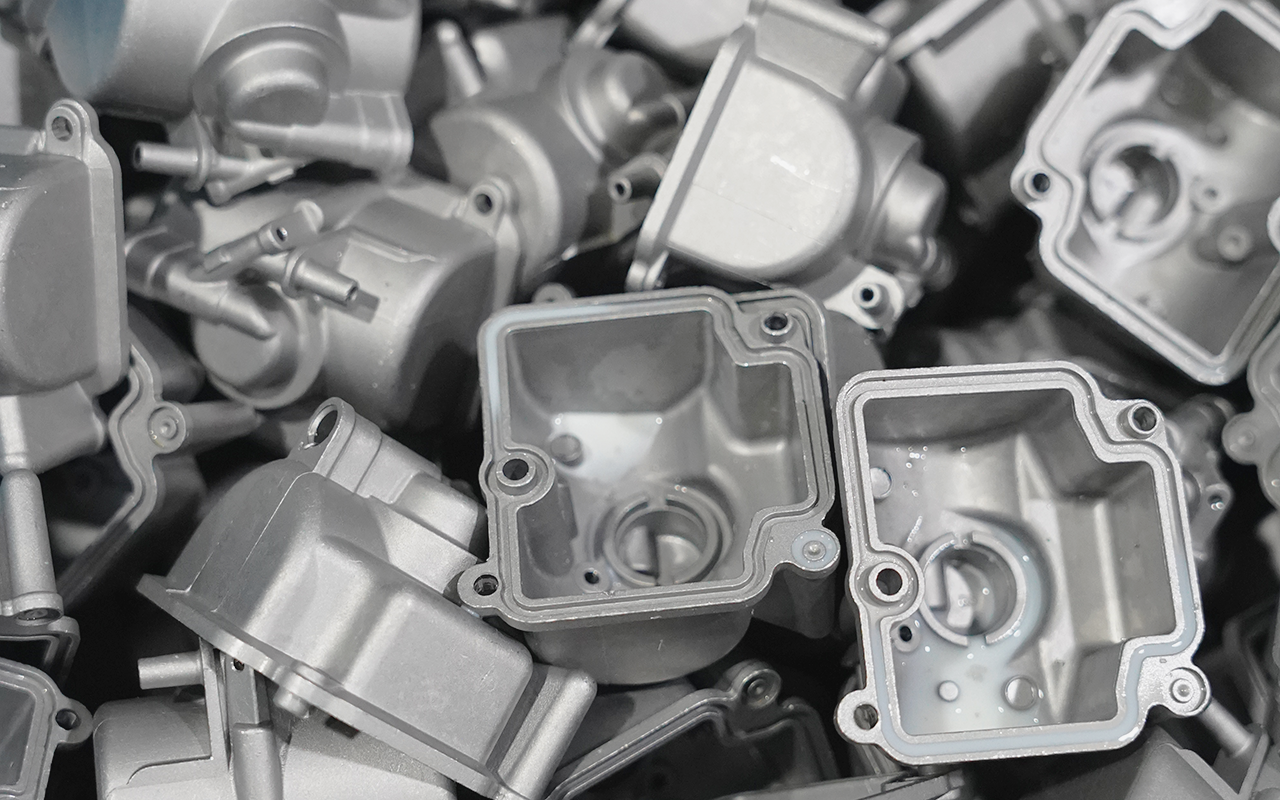

The carburetor is a core component of fuel-powered equipment, and the carburetor lower cover, as its key part, undertakes core functions such as sealing protection and oil circuit regulation. Currently, the carburetor lower cover mass-produced by CPO Cool Power’s factory has become an important component ensuring the stable operation of power systems, widely concerned by the industry, relying on precise design, high-quality materials and strict standards.

Precision Structural Design: Fortifying the Core of Sealing and Regulation

The carburetor lower cover is a key encapsulation component of the float chamber, with the core function of sealing the chamber to prevent fuel leakage and providing a stable installation foundation for oil circuit components. CPO Cool Power’s carburetor lower cover adopts a hollow structure, accurately matching the assembly dimensions, and reserves a negative pressure channel interface to ensure smooth conduction. The product optimizes the design of the oil drain threaded hole and special screws at the inclined lower part, improving the convenience of oil drain and sealing reliability. The sinking platform structure at the bottom further ensures the flatness of the sealing surface, consolidating the core performance.

High-Quality Material Selection: Ensuring Performance and Service Life

Materials are the key to determining product performance. Combining the working environment of the carburetor, which is subject to temperature changes, fuel corrosion and mechanical vibration, CPO Cool Power selects aluminum-zinc alloy as the production material. This alloy has the advantages of high strength, light weight and corrosion resistance, which can resist fuel aging, extend service life, and has excellent thermal conductivity, which can assist in heat dissipation to avoid unstable fuel atomization and improve fuel economy.

Strict Production Process: Forging Class A Quality Standards

In terms of production process, CPO Cool Power’s factory has introduced advanced equipment to build a full-process refined production system. After precision die-casting forming, the product undergoes CNC precision machining to ensure assembly accuracy. Each batch undergoes 100% full inspection of dimensions, sealing, strength and other indicators to ensure Class A quality. Strict control enables it to be compatible with various power equipment such as motorcycles and all-terrain vehicles, stably play a role in high-performance scenarios, and improve the stability of power output.

Precise Positioning: Adapting to Diverse Scenarios and Needs

CPO Cool Power takes “precise matching and stable reliability” as its core positioning. The carburetor lower cover mass-produced this time inherits the high-quality gene of the company’s products and solves industry pain points. The product can be used as original equipment supporting parts and after-sales replacement parts, with strong adaptability. At present, the factory has large-scale mass production capacity, can provide customized services, and direct supply from the manufacturer ensures quality and cost performance, helping to expand the global market share.

The quality of the carburetor lower cover directly affects the performance and user experience of the power system. CPO Cool Power’s carburetor lower cover builds a solid quality defense line with design, materials and craftsmanship. In the future, with the further release of production capacity and in-depth research and development, the company will continue to provide high-quality parts for the global power equipment industry, helping the high-quality development of the industry.

CONTACT US!

Address

No. 8 Zhongxing Road, Guanling Town, Fuding City, Fujian Provi, China

Email Us

China : [email protected]

Indonesia agent : [email protected]

Thailand agent : [email protected]

Call Us

China General Manager : +86 180-5972-7660

China Sales Manager : +86 187-5038-9478

Indonesia General Manager : +62 811-124-2882

Thailand General Manager : +66 080-277-5290

* Sincerely recruit agents from all countries

Contact information:

General Manager Tel:+86 180-5972-7660

Email:[email protected]